Anyways thats out of the way - no issues assembling. I have a mix of HAYES and firestone lockrings. The last one isn't seated as nice as the other 3 and the only other lockring I have is not round as I found out...more of an oval. How do you straighten these springy things? i got the 4 bent back straight by kinda bending and bouncing on them and that worked but this one is bent all weird. it lays flat and the ends meet but apparently is egg shaped when put on a rim.

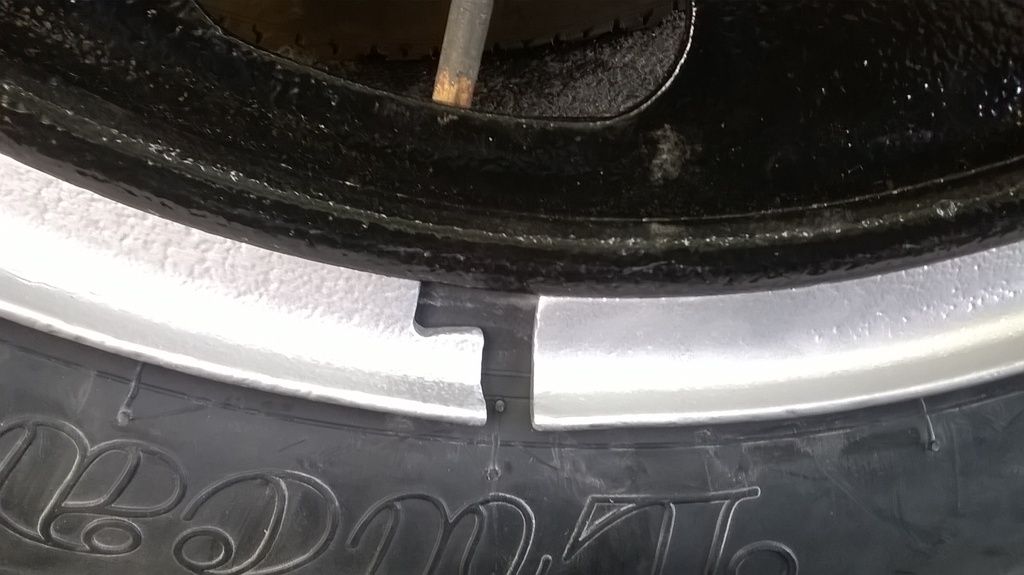

firestone - i followed the assembly directions and tamped the ring down - its fully seated but ended up with this gap which appears normal

HAYES - fully seated and not quite touching.

other questionable HAYES - as you can see the last little bits arent fully seated due to being bent. Is this a safety concern? any way to straighten? i tried a 3 lb sledge and a steel bar to try to bend it in more but thats a far as it wants to go. it is fully seated the rest of the rim.

tires only have less than 5 lbs of air in them so dont worry.